Precision Paper Converting,

Built on Over a Century of Experience.

For over a century, we've specialized in slitting, rewinding, sheeting, trimming, die cutting, and more — delivering precision and versatility with every cut.

Let's Roll.

About Us: A Legacy Built on Paper

Founded in 1912 by Ross A. Cauthorn, Cauthorne Paper Company has a rich history rooted in integrity, innovation, and strong relationships. From supporting local mills during the Great Depression to becoming a trusted supplier for major newspapers like The Wall Street Journal and The Washington Post, our commitment to quality and service has spanned over a century.

Family-owned for four generations, the company has evolved while staying true to its core values. Today, under the leadership of Mark Williams, we continue to honor our legacy while adapting to the future of paper distribution and converting.

Our Services

Our goal is to employ our products, services, and skills to help our customers achieve their goals. We can assist with R&D projects and raw material sourcing. We want to be a value-added supplier.

In addition to custom slitting, sheeting and die-cutting, we have experience with and access to a wide variety of paper and paperboard products.

Reach out to the Paper Doctor, Steve Newsome, with any material questions!

Slitting & Rewinding

Our paper slitting rewinding services are customized to the specific needs of our customers. We can slit a variety of materials to custom widths and rewind to custom lengths or roll sizes.

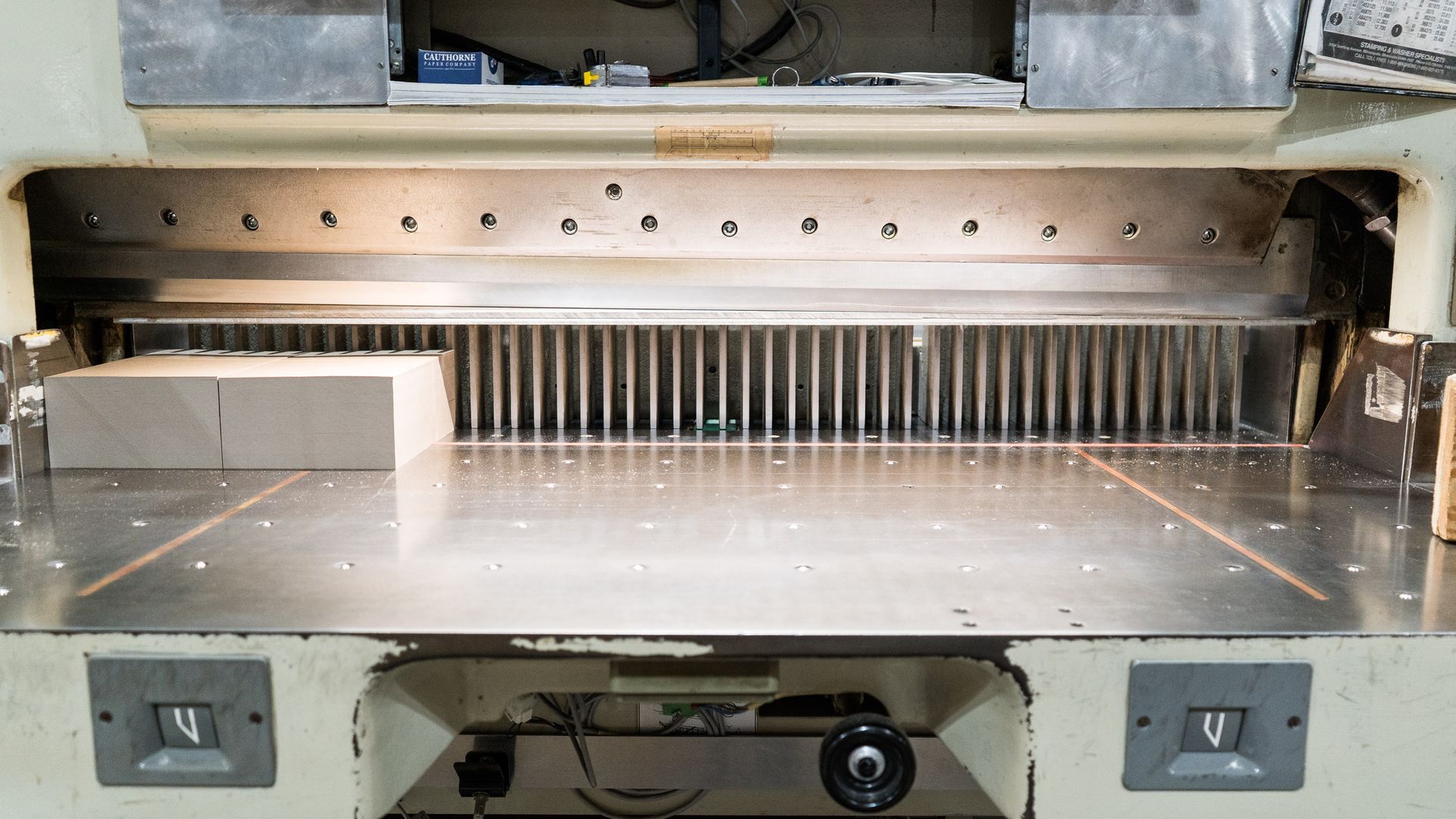

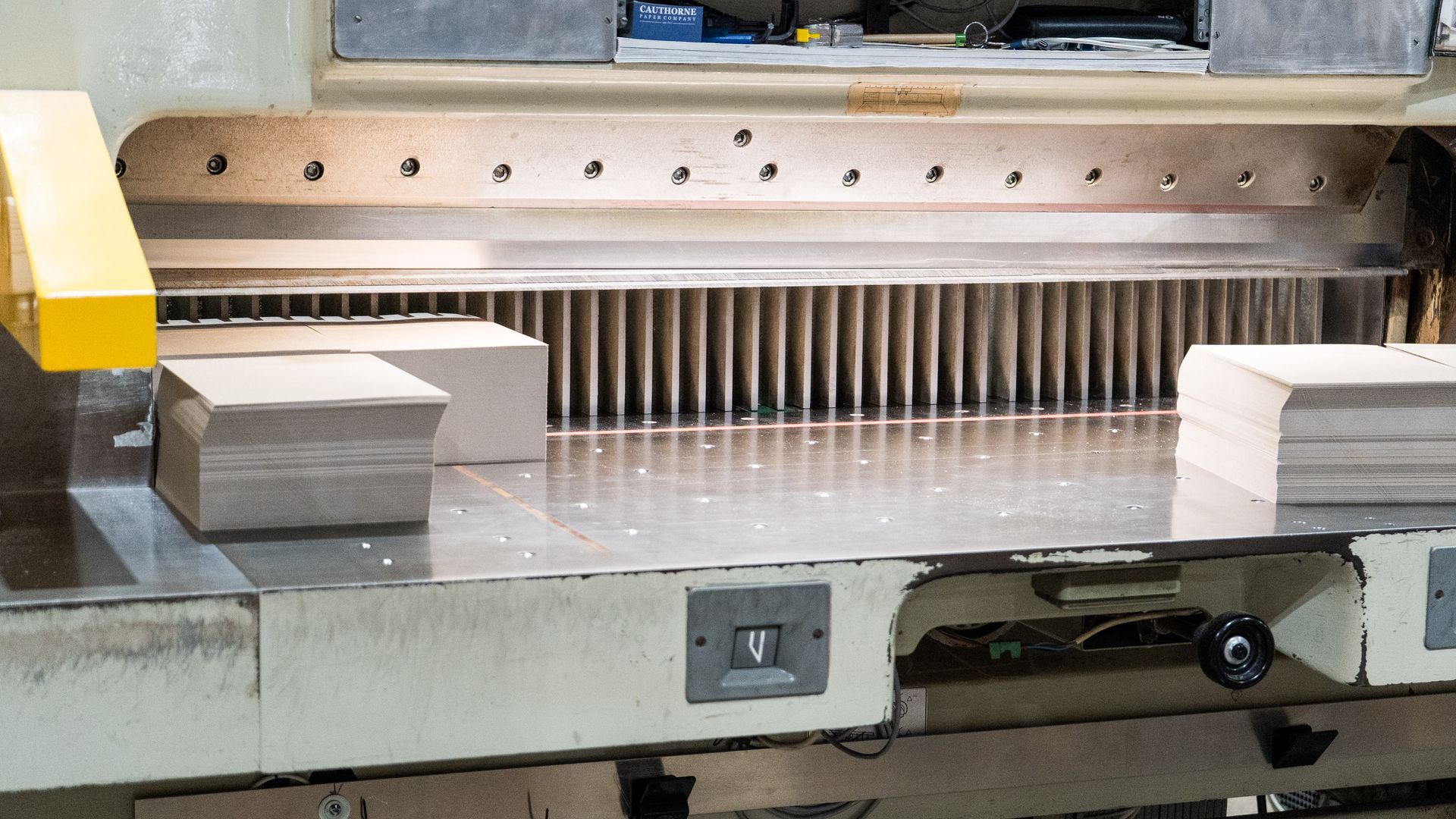

Sheeting

After slitting rolls of paper to the desired width, sheets can be cut to length on our Sheeter. If necessary, lengths shorter than the minimum length our Sheeter can cut can be cut on one of our three guillotine trimmers.

Die Cutting

Our die cutting capabilities allow us to make an infinite variety of shapes and styles. We can die cut a wide range of chipboard, folding carton and micro-flute corrugated board. We have design software and a Gerber sample table to cut prototypes for customers.

Industries Commonly Served

Paper Distributors

Reliable paper grades and custom converting services to support your distribution needs.

Cold Chain Supply

Durable, moisture-resistant paper products tailored for temperature-sensitive logistics.

Blade Manufacturing

Precision-cut substrates and interleaving materials designed for blade production and packaging.

Pesticide (Chemical Manufacturing)

Chemical-resistant papers and custom solutions for secure product containment and labeling.

Performance Fibers (Non-woven Textiles)

Paper materials engineered for strength, compatibility, and seamless integration with non-woven processes.

Packaging & Manufacturing

Versatile paperboard and converting services optimized for industrial packaging and production lines.

Why Choose Us

Strong Supplier Relationships

Built on trust since 1912, our partnerships with top mills ensure access to the highest quality materials.

Industry Expertise

With over a century in the paper converting business, we bring unmatched knowledge and craftsmanship to every project.

Flexible Production Capabilities

From large-scale runs to custom orders, our team adapts to meet your unique needs with precision and efficiency.

Family-Owned Integrity

Built on generations of Cauthorne family leadership, the company was entrusted to us in 2018. Today, we proudly continue its legacy as a family-run business dedicated to integrity and customer success.

Quality Policy

ISO certification

Cauthorne Paper Company is committed to:

- Satisfying the requirements of our customers

- Satisfying the requirements of statutes and regulations applicable to our business

- Utilizing our quality management system to improve our business

- Setting and working to achieve quality objectives that support our business strategy

We believe in:

Stewardship

For over a century, we've cared for our customers, employees, and community. From supporting local mills during the Great Depression to building strong supplier relationships, doing the right thing has always been at the core of who we are.

Thoughtfulness

Our success comes from thoughtful decisions and attention to detail. From investing in our first paper sheeter to serving major newspapers like The Wall Street Journal, we've built a reputation for quality and care.

Persistance

Through changing times and challenges, we've remained steady. Four generations of leadership and over 100 years later, our commitment to innovation and service continues to move us forward.

The Rollout

Behind the Scenes